Industry News

-

All relevant personnel LOTO compliance

The Lockout tagout process is very effective, but it is not simple, so it should not be learned before going inside the logistics equipment. Safe entry into the machine and Lockout tagout operations must be performed only by trained and authorized personnel. Considering that the maintenance work ...Read more -

How to use Lockout Tagout to enter logistics equipment safely?

1.Distinguish the types of work Operations into logistics equipment can be divided into two types. The first is to have to deal with simple routine, repetitive operations such as dropping containers and trays, and to do so within sight and to follow procedures for safe entry into the machine. Sec...Read more -

Lock out tag out-Steel mill risks

1. Do not wear safety belt when working at height On April 25, an inspection found that the construction workers of Shandong Metallurgical Design Institute Co., Ltd. climbed down to the bottom of the rainwater collection pond scaffold from the material yard of Zhongjin Construction Project in Yul...Read more -

Lockout Tagout validation pilot work

In order to put an end to the unsafe factors of people, starting from the concept of essential safety and effectively preventing injuries caused by operators’ misoperations, copper Branch took power workshop as a pilot to carry out the implementation of energy isolation “Lockout tagou...Read more -

Standard LOTO steps

Step1 – Prepare for Shutdown 1. Know the problem. What needs fixing? What dangerous energy sources are involved? Are there equipment specific procedures? 2. Plan to notify all affected employees, review LOTO program files, locate all energy lock-in points, and prepare appropriate tools and ...Read more -

Lockout tagout – Article 10 HSE prohibition

Article 10 HSE prohibition: Work safety ban It is strictly prohibited to operate without authorization in violation of the operation rules. It is strictly prohibited to confirm and endorse the operation without going to the site. It is strictly forbidden to command others to do risky operations i...Read more -

Preheater hidden trouble detection criteria

Preheater hidden trouble detection criteria 1. Preheater (including calciner) running Preheater platform, components and guardrail should be complete and firm. Air gun and other pneumatic components, pressure vessels work normally, the flap valve should have reliable locking device. Preheater man...Read more -

Inspection standard for hidden danger of rotary kiln system

Inspection standard for hidden danger of rotary kiln system 1. Rotary kiln operation Observation door (cover) of rotary kiln head is intact, platform guardrail and sealing device are intact without falling off. The rotary kiln barrel body has no obstruction and collision objects, the manhole door...Read more -

Safety production -LOTO

On September 2, Qianjiang Cement company organized the “safety first, life first” safety education and training, the company’s director Wang Mingcheng, the head of each department, technical personnel and front-line employees, contractors and a total of more than 90 people atten...Read more -

Locking, tagging and controlling dangerous energy in the workshop

OSHA instructs maintenance personnel to lock, tag, and control hazardous energy sources. Some people don’t know how to take this step, every machine is different. Getty Images Among people who use any type of industrial equipment, lockout/tagout (LOTO) is nothing new. Unless the pow...Read more -

Control of hazardous energy: unexpected danger

An employee is replacing the ballast in the ceiling light in the break room. The employee turns off the light switch. Employees work from an eight-foot ladder and begin to replace the ballast. When the employee completes the electrical connection, the second employee enters the dark lounge...Read more -

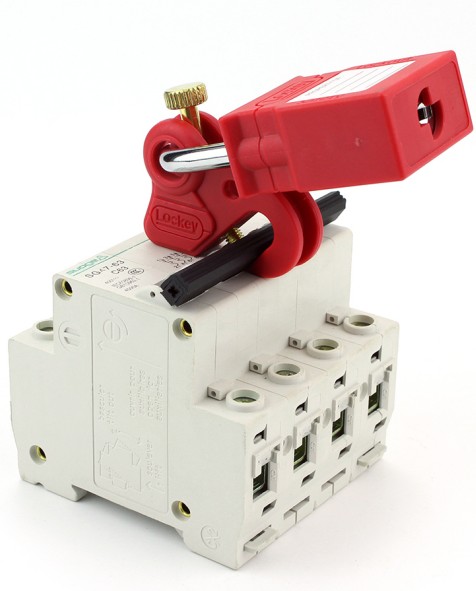

Lock-out/tag-out (LOTO) system

Johnson also recommends the use of a lock-out/tag-out (LOTO) system. The Pennsylvania Extension Services website states that the lock/tag system is a process used to mechanically lock equipment to prevent the machine or equipment from being energized to provide worker protection. Th...Read more