An employee is replacing the ballast in the ceiling light in the break room. The employee turns off the light switch. Employees work from an eight-foot ladder and begin to replace the ballast. When the employee completes the electrical connection, the second employee enters the dark lounge. Not knowing the work being performed on the ceiling light, the second employee toggled the light switch to turn on the light. The first employee received a slight electric shock, causing him to fall from the ladder. During the fall, the employee stretched out his hand to prepare for landing, causing a broken wrist. The injury required surgery, and the employee was hospitalized overnight.

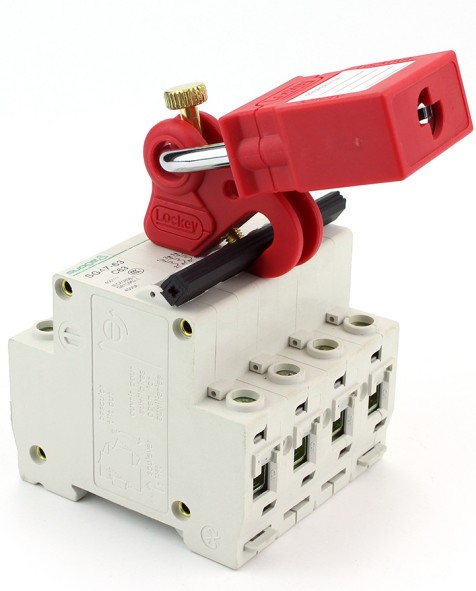

Although the previous scenario is hypothetical, the lockout and tagout procedure accurately describes the potential harm that may occur when the dangerous energy is not controlled. Hazardous energy can be electrical energy, mechanical energy, pneumatic energy, chemical energy, thermal energy or other energy. If it is not properly controlled or released, it may cause the equipment to operate unexpectedly. In this example, the employee servicing the light should have isolated the circuit at the circuit breaker and initiated the lock-out and tag-out (LOTO) procedure. The power supply at the isolation circuit breaker can prevent injury when the light switch is activated. However, simply turning off the power to the circuit breaker is not enough.

When external service personnel engage in activities within the scope and application of this standard, the on-site employer and the external employer shall notify each other of their respective lock-out or tag-out procedures. It is also necessary to install devices that use positive means such as keys or password-type locks to keep the energy isolation device in a safe position and prevent the machine or equipment from being energized.

OSHA requirements related to hazardous energy control standards can be found in 29.CFR.1910.147. This standard requires employers to formulate a LOTO policy in the repair and maintenance of machinery and equipment, when the accidental power-on or start-up of the machinery or equipment, or the release of stored energy may harm employees. Employers must develop plans and use procedures to secure appropriate locking devices or tagging devices to energy isolation devices, and otherwise disable machines or equipment to prevent accidental power-on, startup, or energy release to prevent injury to employees.

A key element of the LOTO plan is a written policy. In addition, the standard requires employers to develop energy control procedures, which means that methods of shutting down and repairing equipment must be documented. For example, if the air conditioning unit needs to be repaired, the process of turning off the power needs to include the name/location of the circuit breaker panel and the circuit breaker number in the panel. If the system has multiple energy sources, then the control program must specify the method of isolating all energy sources. Before starting work on locked or listed machines or equipment, employees must confirm that the equipment has been isolated and powered off.

Other key elements of the LOTO plan include employee training and regular inspections of the LOTO procedures. Training is required for job assignment and must include training in identifying hazardous energy sources, the type and amount of energy available in the workplace, and the methods and means required for energy isolation and control. When the scope of work changes, the installation of new machines or changes in processes may bring new dangers, further training is required.

Periodic inspections are only an annual audit of these procedures to verify the accuracy of the procedures or to determine the changes or corrections that must be made to the procedures.

The terminal owner or operator must also consider the contractor’s LOTO procedures. External contractors should implement their own LOTO procedures when dealing with systems such as electrical, HVAC, fuel systems or other equipment. Whenever external service personnel engage in activities covered by the scope and application of the LOTO standard, the on-site employer and the external employer must inform each other of their respective lock-out or tag-out procedures.

Post time: Sep-04-2021