News

-

Inspection and maintenance work safety management

Inspection and maintenance work safety management In order to do a good job in the safety management of inspection and maintenance operations of the company, implement relevant national safety laws and regulations, standards and specifications, standardize the energy locking procedures of mainten...Read more -

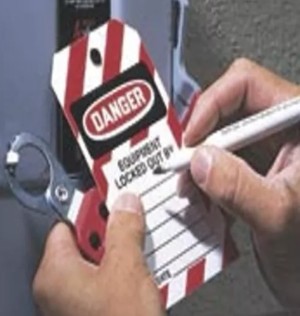

Energy Isolating Device

Tagout is the process by which an energy-isolating device used for lockout is placed in the off or safe position and a written warning is attached to the device or placed in the area immediately adjacent to the device. The tag must identify the person who applied it and be durable and able to wit...Read more -

Equipment safety work

Modern machinery can contain many hazards to workers from electrical, mechanical, pneumatic or hydraulic energy sources. Disconnecting or making the equipment safe to work on involves the removal of all energy sources and is known as isolation. Lockout-Tagout refers to the safety procedure used i...Read more -

Energy isolation safety training

Energy isolation safety training Xianyang Project Department organized all managers to study the case of a petrochemical flash explosion accident on July 14 in the conference room. Combining the foam tank farm of pipeline construction, the project department of HSE director did a special energy i...Read more -

Energy isolation for safety

Energy isolation for safety What exactly is energy isolation? Energy refers to the energy contained in process materials or equipment that may cause injury to persons or damage to property. The purpose of energy isolation is to prevent the accidental release of energy (mainly including electric e...Read more -

Thinking and discussion on safe production

Thinking and discussion on safe production At 12:20 PM on November 30, 2017, a petrochemical company refinery workshop ii of 1.5 million tons/year heavy oil catalytic cracking unit slurry steam generator E2208-2 during maintenance, in the process of dismantling the equipment head bundle jumped ou...Read more -

Lockout tagout validation

Lockout tagout validation Since the power workshop organized the workshop management personnel and the responsible person of each process, the team leader and the repair group personnel to carry out the training on the implementation rules and operation of the energy isolation “lockout tago...Read more -

Lockout Tagout Training class

Lockout Tagout Training class In order to improve the professional and technical personnel of the “energy isolation lockout Tagout” work understanding and awareness, promote the “energy isolation lockout tagout” work more solid, effective development, recently, The equipme...Read more -

LOTO & Mechanical Protection

LOTO & Mechanical Protection From November 29 to December 5, L team invited HSE team to conduct the line level “LOTO & Mechanical Protection” minesweeper to further improve staff’s understanding of LOTO and mechanical protection, while each SG Lead conducted its own revi...Read more -

December Security training — Lockout Tagout

December Security training — Lockout Tagout The accident after At around 8:20 am on January 25, 2018, a labor dispatch employee of an LG production line entered the stamping machine to replace the production date mold. Instead of locking the power switch on the press, the dispatcher pressed...Read more -

Lockout Tagout operation procedure

Lockout Tagout operation procedure Duties and responsibilities 1. Manager of the department where the device is locked 2. Report to manager or EHS if Lockout tagout procedure is not implemented by employees in the department. 3. Director of the department where the device is locked 4. The depart...Read more -

Lockout Tagout job operation

Lockout Tagout job operator The operator must read this procedure carefully and strictly comply with all Lockout tagout requirements; 2.Lockout tagout operators must be trained and warned before they can work; Operators are also required to undergo retraining every two years; 3. The Lockout tagou...Read more