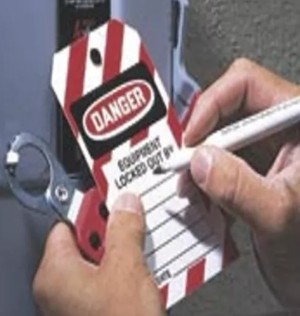

Lockout Tagout job operator

The operator must read this procedure carefully and strictly comply with all Lockout tagout requirements;

2.Lockout tagout operators must be trained and warned before they can work; Operators are also required to undergo retraining every two years;

3. The Lockout tagout operator shall coordinate, discuss or consult with the supervisor in time if he/she encounters any problem during the process of testing this procedure.

After Lockout tagout, confirm:

1. Hazardous energy and materials have been isolated or removed (e.g., releasing energy or materials and observing pressure gauges, mirrors or level indicators to confirm that stored hazardous energy has been removed or properly blocked; The visual component has been disconnected and the rotation of the equipment has stopped);

2.Check that the power supply lead is disconnected, and the lock must be physically disconnected and no voltage is tested.

Lockout tagout points

1. Identify all hazardous energy sources before activating Lockout Tagout.

2. Prior to the operation, ensure that appropriate isolation at work is in place and that relevant isolation is secured;

3. Persons entering locked areas should consider possible exposure to hazards;

4.Communication;

5.Hazards will be considered before energy removal;

6.Effective test procedures must be implemented;

7.For all electrical hazards, must carry out power test; Eight. “Lock up” and “do not activate equipment sign” are sacrosanct measures!

Post time: Dec-11-2021