Workshop energy isolation implementation code

1. When energy isolation work is involved in the workshop, standard operation shall be carried out according to the Energy Isolation Management Regulations of a branch Company

2. Both locking and blind plates are energy isolation methods of the process system. When the whole system or single unit of the production plant is stopped for maintenance, the blind plate isolation measures in the boundary area should be implemented after the material return and replacement, which in essence is also the embodiment of the principle of energy isolation.

3. Effective measures must be taken to implement energy isolation and complete partition of material unit for local excision and maintenance of some units, monomer or regional equipment and pipelines of the production plant. When the isolation room is selected, the blind plate isolation is preferred in principle for the flange connected equipment and pipes.

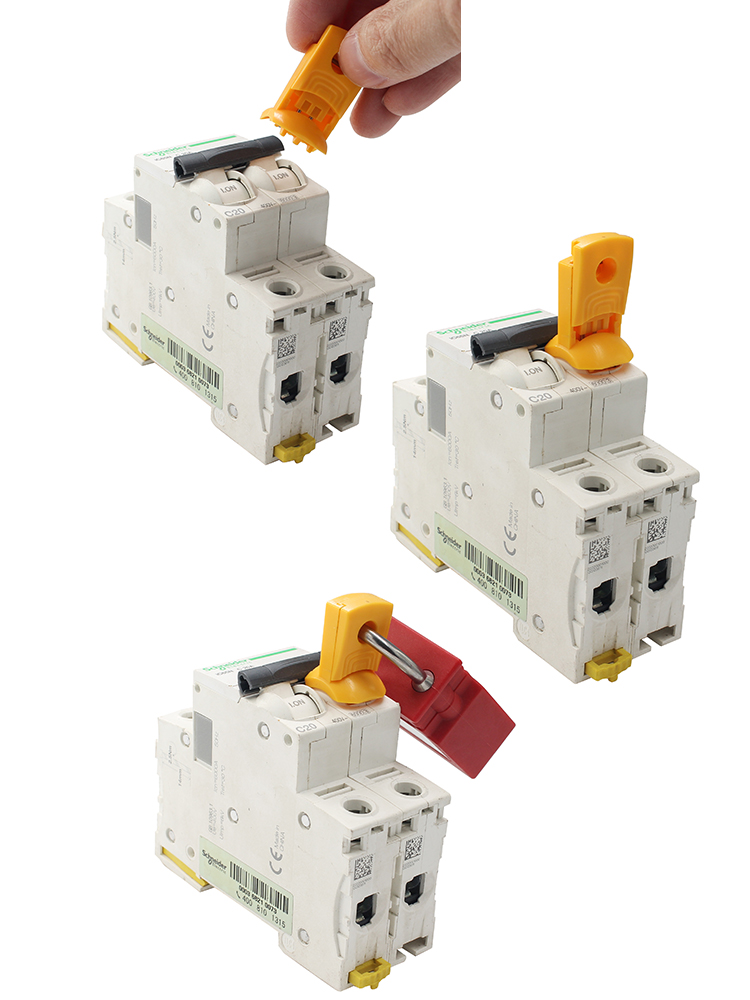

4. Lockout tagout isolation mode must be adopted for process pipes and equipment without blind plate isolation during operation. Before the implementation, the project leader of the relevant workshop (a workshop, maintenance workshop, power supply workshop) should identify the risks of the system and judge the effectiveness of Lockout tagout (listing is filled in by the territorial unit) isolation mode, and strictly follow the relevant safety regulations of the company to confirm the conditions. According to the “Energy Isolation Management Regulations”, the filter screen is not locked when cleaning, and the single operation card of the process is executed.

Post time: Dec-17-2022