News

-

Physical Description of a Tag

Physical Description of a Tag A lockout/tagout tag can come in a variety of different designs. Choosing the one that works best for your facility will help ensure they are easily recognizable. While you can pick any design you would like, it is best to stick with only one design at all times so t...Read more -

What is the LOTO Procedure?

What is the LOTO Procedure? The LOTO procedure is a pretty straight forward safety policy that has saved thousands of lives and prevented many more injuries. The exact steps taken will vary some from company to company, but the basic requirements are as follows: Power is Disconnected – The first ...Read more -

What other tools should be used in a lockout/tagout strategy?

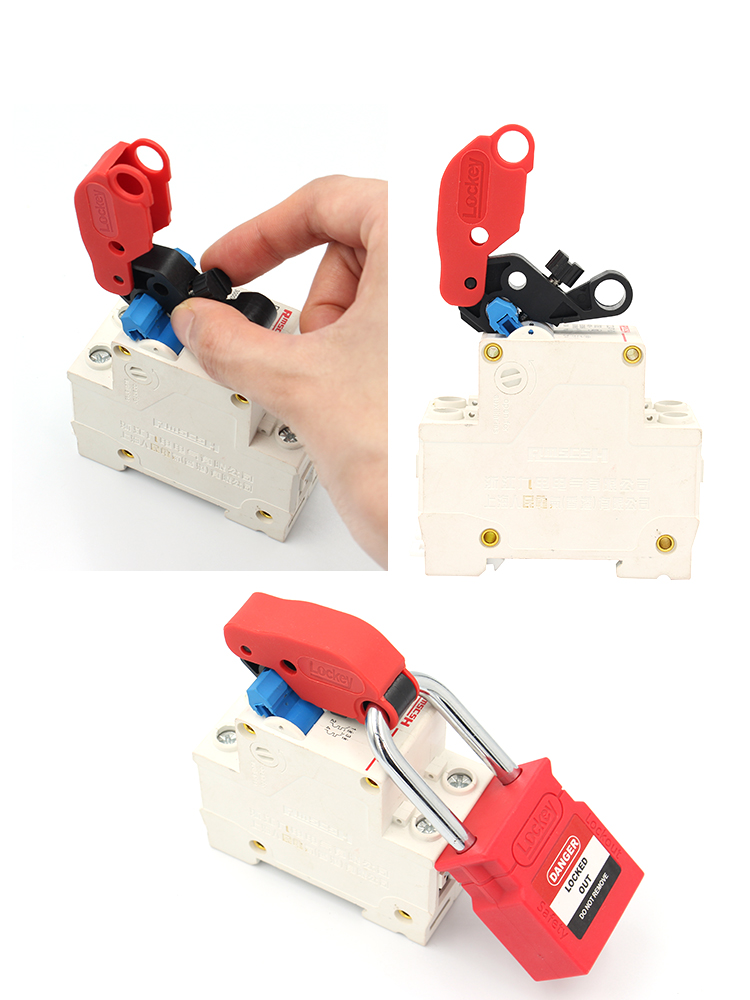

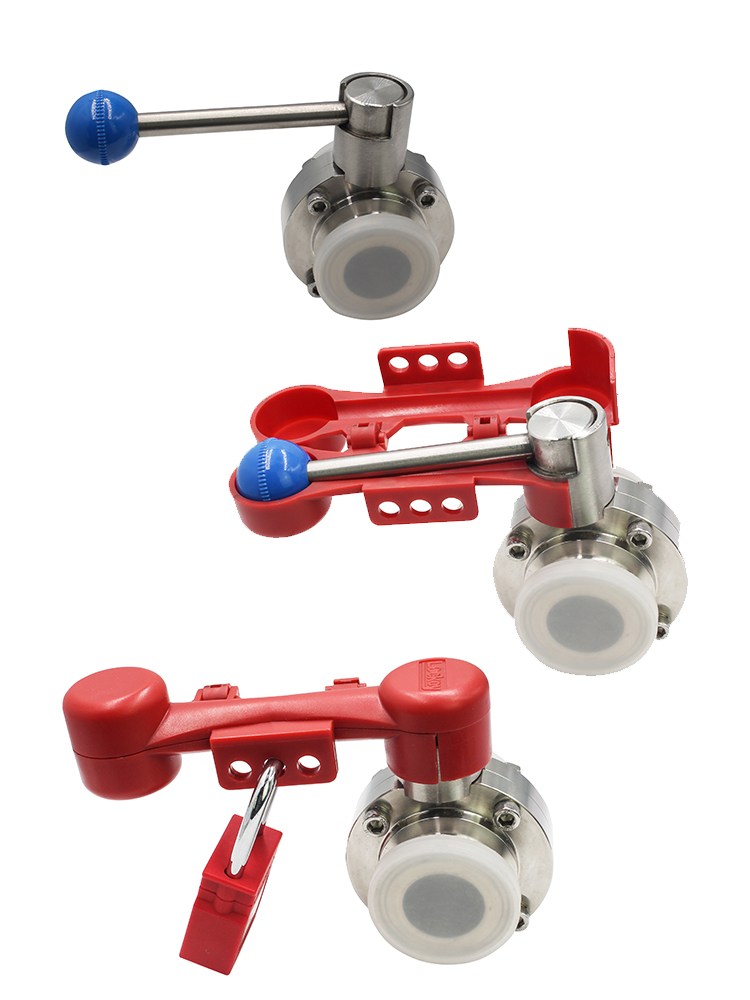

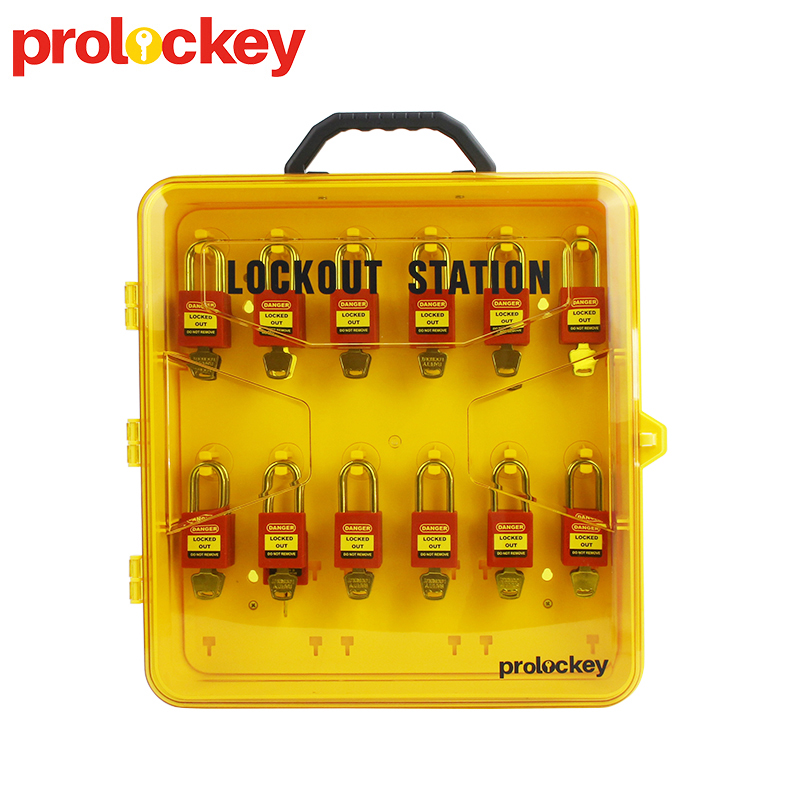

Proper locks: Having the right type of locks will go a long way toward ensuring lockout/tagout is successful. While you technically can use any type of padlock or standard lock to secure power to a machine, a better option is locks that are made specifically for this purpose. A good lockout/tagou...Read more -

What are machine-specific lockout/tagout procedures?

Lockout/tagout (LOTO) is a program that physically removes the sources of power to a machine, locks them out, and has a tag in place that indicates why the power was removed. This is a safety procedure that is used whenever someone is working in or around a dangerous area of a machine to ensure i...Read more -

Where should lockout/tagout tags be placed?

Placed with the Locks Lockout/tagout tags should always be placed with the locks that are used to prevent power from being restored. The locks can come in many different styles including padlocks, pin locks, and many others. While the lock is what will physically stop someone from restoring the p...Read more -

Lockout Tagout Products

Lockout Tagout Products A number of options exist for implementing lockout tagout procedures in a facility. Some facilities choose to create their own systems using custom products and equipment. This can be effective as long as everything follows OSHA standards and other proven best practices. T...Read more -

Understanding Lockout/Tagout Programs

Understanding Lockout/Tagout Programs Understanding this type of program comes down to training employees on the correct precautions and procedures that they must take to stay safe and prevent unexpected releases of hazardous energy. Employee training for both affected employees and LOTO authoriz...Read more -

Steps to a Lockout/Tagout Procedure

Steps to a Lockout/Tagout Procedure When creating a lockout tagout procedure for a machine, it is important to include the following items. How these items are covered will vary from situation to situation, but the general concepts listed here should all be addressed in every lockout tagout proce...Read more -

Who needs LOTO Training?

Who needs LOTO Training? 1. Authorized employees: These workers are the only ones allowed by OSHA to perform LOTO. Each authorized employee must be trained in the recognition of applicable hazardous energy sources, the type and magnitude of energy sources available in the workplace, and the metho...Read more -

About Safety Lockout/Tagout

About Safety Lockout/Tagout Safety Lockout and Tagout procedures are meant to prevent work accidents during maintenance or service work on heavy machinery. “Lockout” describes a procedure in which power switches, valves, levers, etc. are blocked from operation. During this process, sp...Read more -

What are lockout/tagout devices?

What are lockout/tagout devices? Placing a physical locking mechanism on either the electrical supply cord or the place where the machinery is plugged in is absolutely necessary when using lockout/tagout procedures. Then a tag, hence the name tagout, must be placed on or near the locking device t...Read more -

Who Requires and Enforces the use of LOTO Devices?

Who Requires and Enforces the use of LOTO Devices? In order to control hazardous energy, lockout/tagout devices are crucial—and required by OSHA standards. The most important one to be familiar with is 29 CFR 1910.147, the Control of Hazardous Energy. The key points in following this standard inc...Read more