New Fashion Design for Large Breaker Lockout - Safety Warning Tag Customized PVC Tags Safety Lockout Tagout LT01 02 03 – Lockey

New Fashion Design for Large Breaker Lockout - Safety Warning Tag Customized PVC Tags Safety Lockout Tagout LT01 02 03 – Lockey Detail:

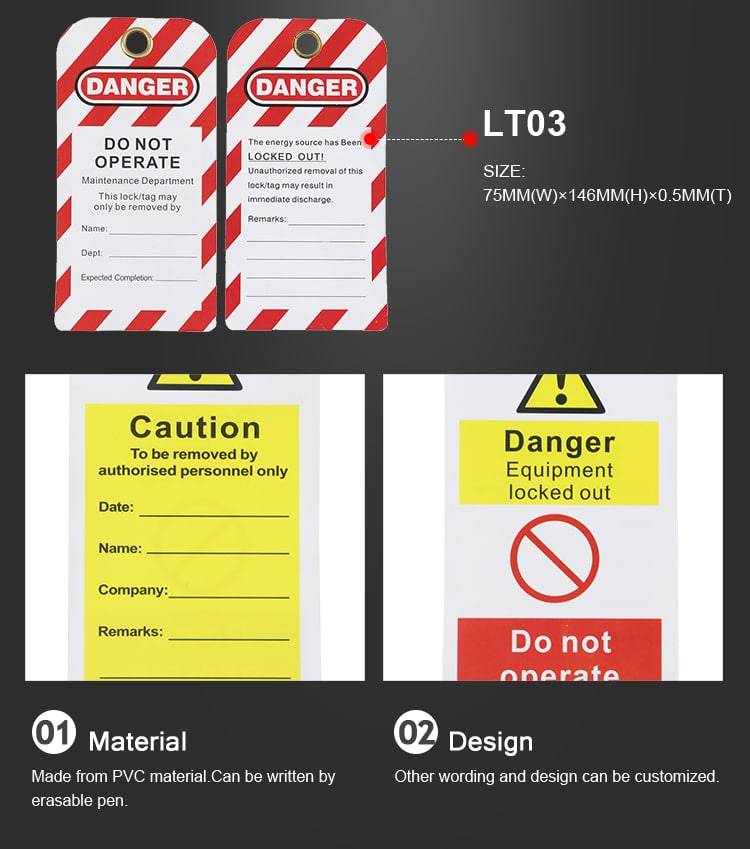

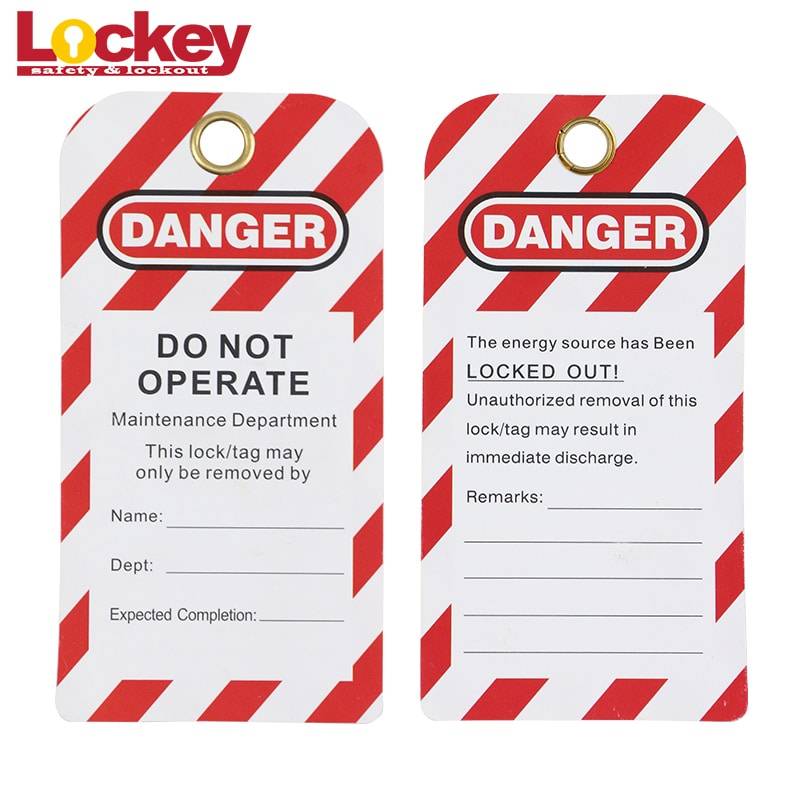

Safety Warning Tag LT01 & LT02 & LT03

a) Made from PVC material.

b) Can be written by erasable pen.

c) Use with padlock to remind that the device has been lockout and can not be operated .It can only be opened by the one who lock it.

d) On tag, you can see “danger /Do not operate/Caution security warning language and also “name /department /date”etc blank for you to fill in.

e) Other wording and design can be customized.

|

Part no. |

Description |

|

LT01 |

75mm(W)×146mm(H)×0.5mm(T) |

|

LT02 |

75mm(W)×146mm(H)×0.5mm(T) |

|

LT03 |

75mm(W)×146mm(H)×0.5mm(T) |

|

LT22 |

85mm(W)×156mm(H)×0.5mm(T) |

Safety Tag (Life Plate)

This item can determine whether to need by everybody’s actual situation, agree with padlock commonly

Safe for

1. The lock must be listed accordingly and indicated on the signboard

The name

department

On the date

Repair information or telephone number can be noted on the back

2. The safety tag is used by authorized personnel together with the life lock.

The purpose is to authorize the personnel to perform maintenance on the equipment, warning and telling the operator not to operate or turn on the equipment.

3. Labels by themselves cannot be used as a means of isolating energy sources.

Types of Signage

Each territorial supervisor shall establish a master label within the territory of this book. The specific information contained in the master label includes: identified and described energy source, locking mode, confirmation mode, relevant risks of lockout and tagout, equipment layout diagram and location of energy isolation point and related risks.

Local signs are directly posted on the equipment near the entrance or security protection area. Local signs contain specific information such as: energy control methods, tasks.

The production of signs

Identification and evaluation

Team members organize to identify and investigate the energy source of the equipment, confirm all energy types, sources, release locations, locations that should be locked and affected employees, and complete the risk identification work.

According to the dangerous characteristics of the maintenance point, the appropriate “warning language” is selected;

Indicate the specific location of the dangerous point to be listed;

Accurately draw the plan of the danger point;

The object and locking point should be controlled in this dangerous position.

The object and locking point should be controlled to evaluate the dangerous position;

Evaluate and classify the number of listings;

Drawing signs;

Draw local signs.

Product detail pictures:

Related Product Guide:

LOTO-Prevent valve misoperation(1)

Lockout Tagout Training Authorized Personnel

So as to provide you with ease and enlarge our business, we even have inspectors in QC Crew and guarantee you our best company and solution for New Fashion Design for Large Breaker Lockout - Safety Warning Tag Customized PVC Tags Safety Lockout Tagout LT01 02 03 – Lockey , The product will supply to all over the world, such as: Accra, Montpellier, Barbados, We also have good cooperation relationships with many good manufacturers so that we can provide almost all of auto parts and after-sales service with high quality standard,lower price level and warmly service to meet demands of customers from different fields and different area.

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.