Adjustable Cable Lockout CB01-4 & CB01-6

Adjustable Cable Lockout CB01-4 & CB01-6

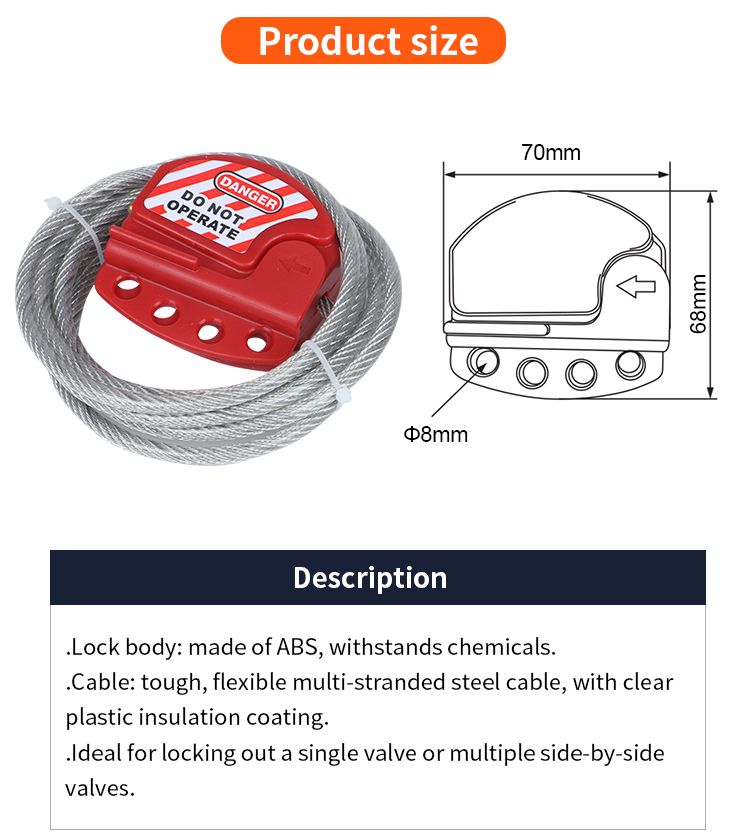

a) Lock body: made of ABS, withstands chemicals.

b) Cable: tough, flexible multi-stranded steel cable, with clear plastic insulation coating.

c) Cable length can be customized.

d) Accepts up to 4 padlocks for multiple lockout application.

e) Includes high-visibility, re-usable, write-on safety labels. Can be customized.

f) Ideal for locking out multiple circuit breaker panels and side-by-side gate valve lockout.

| Part No. | Description |

| CB01-4 | Cable diameter 4mm, length 2 m |

| CB01-6 | Cable diameter 6mm, length 2 m |

This Lockey Adjustable Cable Lockout is an integrated safety lockout hasp and cable for multiple circuit breaker panels and side-by-side gate valve locks. Its cable adjusts for a secure fit by cinching it tight to remove slack with the locking feature. The tough, flexible multi-stranded steel cable is insulated with a clear plastic coating (PVC-free). A lightweight thermoplastic body helps withstand chemicals to perform effectively in extreme conditions. In addition, the lockout features high-visibility, re-usable write-on safety labels that identify the responsible person and then can be erased for the next job. These are available in English, Spanish, and French. Suitable for multiple circuit breaker panels and side-by-side gate valve lockouts and group lockout applications as part of a comprehensive OSHA-compliant lockout/tagout safety program.

When do you use safety locks?

Safety locks are usually used when they are in close proximity to equipment for repair or maintenance to prevent emergencies that could result in injury.

When do you use safety locks?

Common occasions: the following occasions, be sure to use safety locks:

1. Safe Lockout tagout should be used to prevent the device from suddenly starting

2. To prevent the sudden release of residual power, it is best to use safety locks to lock:

3. Safety locks should be used when guards or other safety devices must be removed or passed through

4. The working range that should be locked when a certain body part is likely to be seized by the machine:

5. Power maintenance personnel should use safety locks for circuit breakers when conducting circuit maintenance

6. When cleaning or lubricating the machine with moving parts, the machine maintenance personnel should use the safety lock for the switch button of the machine

The U.S. Occupational Safety and Health Administration (OSHA) recommends that all businesses provide safety locks for their employees. Within the workplace, it is the responsibility of the enterprise to track the system chosen for use. The safety lock is not a power extinguishing tool and can only be locked when the power source is isolated.